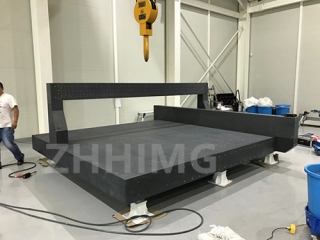

Isku-dhafka granite ee saxda ah waxaa loola jeedaa habka wax soo saarka kaas oo ku lug leh isticmaalka si taxadar leh loo gooyay iyo qaybaha granite ee loo isticmaalo isku dhafka qalabka kala duwan.Isku-dhafka saxda ah ee granite wuxuu leeyahay codsiyo kala duwan, oo ay ku jiraan horumarinta alaabta qalabka kormeerka ee LCD.

Alaabta Kormeerka Gudida LCD:

Alaabta baadhista guddida LCD waa aalado elektaroonik ah oo loo isticmaalo xakamaynta tayada muraayadaha dareeraha crystal (LCD).Waxay caawiyaan in la ogaado cilladaha kala duwan sida gubashada iyo pixels dhintay, hubinta dhalitaanka midabka saxda ah, iyo dhalaalka ugu fiican.Isku-dhafka granite ee saxda ah ayaa wax ka beddelay horumarinta aaladahaas, si weyn u wanaajiyay shaqadooda, iyo tayada muraayadaha LCD ee ay kormeeraan.

Codsiyada Golaha Saxda ah ee Granite ee Horumarinta Aaladaha Kormeerka Gudigga LCD:

1. Heerka saxda ah:

Qaybaha Granite waxaa loo isticmaalaa si loo abuuro meel siman oo muraayadaha LCD la dhigo inta lagu jiro kormeerka, hubinta si sax ah oo sax ah.Qaybaha granite ee loo isticmaalo tan si fiican ayaa loo habeeyay si loo gaaro saxsanaan sare iyo xasilooni, taas oo dammaanad qaadaysa saxnaanta sare ee kormeerka.

2. Xasilooni iyo Waarta:

Qaybaha Granite waxay ka mid yihiin walxaha ugu xasiloon uguna raagaya ee loo isticmaalo qodobka saxda ah ee qalabka baadhista guddi LCD.Waxay bixiyaan madal ka-hortagga gariirka qalabka kormeerka, kaas oo dammaanad qaadaya saxnaanta oo kor u qaadaysa waxqabadka.Xasiloonida qaybaha Granite waxay si weyn u yaraynaysaa kharashka dayactirka qalabka waxayna u ogolaataa soo saarista qalab sax ah oo u adkeysan kara xaaladaha adag iyo deegaanka.

3. Dejinta kulaylka:

Mid ka mid ah sifooyinka gaarka ah ee qaybaha granite waa inay leeyihiin xasillooni kuleyl gaar ah.Dabeecaddan ayaa ka dhigaysa mid ku habboon in loo isticmaalo soo saarista aaladaha kormeerka LCD-ga maadaama ay si fiican u shaqeeyaan xitaa marka lagu jiro kala duwanaanshaha heerkulka jawiga.Xasiloonida kulaylka ee ay bixiso qaybaha isku dhafka granite ee saxda ah waxay hubisaa in muraayadaha LCD lagu eego xaaladaha heerkulka ugu fiican, sidaas darteed lagu gaaro saxnaanta ugu badan iyo soo saarista ugu fiican, alaab tayo sare leh.

4. Heerarka Qalabaynta Tayada Sare:

Qaybaha isku dhafka granite ee saxda ah ayaa loo isticmaalaa si loo horumariyo heerarka cabbiraadda ee loo isticmaalo soo saarista agabka baadhista guddi LCD.Heerarka tayada tayada sare leh waxay dammaanad qaadayaan in aaladuhu ay buuxiyaan saxnaanta, saxnaanta, iyo heerarka xasilloonida ugu sarreeya ee looga baahan yahay buuxinta dalabaadka suuqa ee muraayadaha LCD-ga tayada sare leh.

5. Khaladka la dhimay:

Khaladaadka aaladaha baarista guddi LCD waxay leeyihiin cawaaqib xumo sababtoo ah waxay horseedi karaan soo saarista boqollaal muraayad LCD ah oo cilladaysan.Qaybaha isku dhafka granite ee saxda ah ayaa si taxadar leh loo soo saaray si loo yareeyo heerka qaladka inta lagu jiro qalabaynta qalabka, sidaas darteed hagaajinta saxda ah iyo saxnaanta kormeerka.

6. Wax soo saarka la xoojiyey:

Qaybaha isku dhafka granite ee saxda ah waxay hagaajiyaan wax soo saarka qalabka kormeerka LCD.Waxay u ogolaadaan soo saarida qalab adag, xasiloon, oo la isku halayn karo oo si degdeg ah oo sax ah u sameeya kormeerid.Waxqabadka sare ee qaybaha isku dhafka granite Precision waxay dammaanad qaadayaan tayada guddiga LCD ee ugu fiican, taas oo yaraynaysa wakhtiga wax soo saarka iyo qashinka alaabta.

Gabagabo:

Marka la soo koobo, isu imaatinka saxda ah ee granite wuxuu door muhiim ah ka ciyaaraa horumarinta alaabada qalabka kormeerida guddi LCD oo tayo sare leh.Waxay bixisaa saxnaanta lagama maarmaanka ah iyo saxnaanta loo baahan yahay si loo soo saaro muraayado LCD ah oo tayo sare leh, sidaas darteed hagaajinta tayada guud ee nolosha.Codsiyada shirarka granite ee saxda ah ee wax soo saarka qalabka kormeerka LCD waxay bixiyaan fursado cusub mustaqbalka tiknoolajiyadan, taas oo sii wadi doonta faa'iidada warshadaha wax soo saarka elektaroonigga ah guud ahaan.

Waqtiga boostada: Nov-06-2023