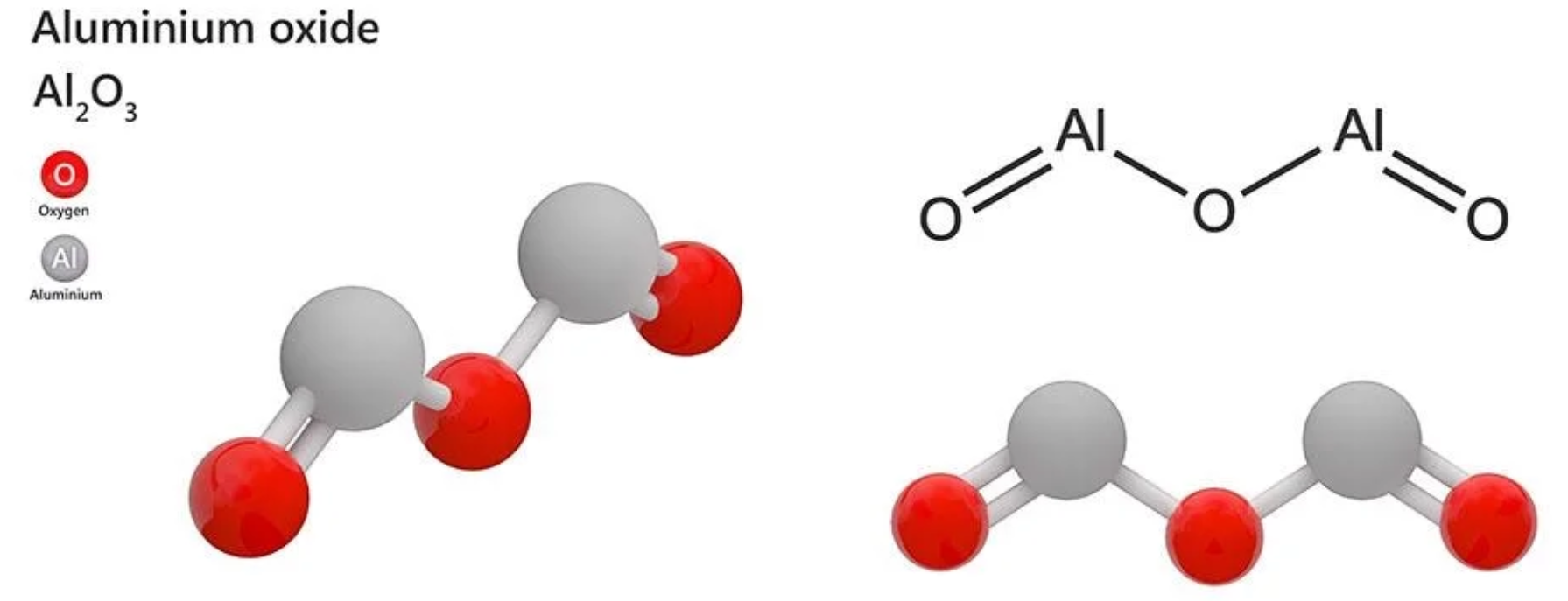

♦Alumina (Al2O3)

Qaybaha dhoobada saxda ah ee ay soo saartay Kooxda Waxsoosaarka Sirdoonka ee ZhongHui (ZHHIMG) waxaa laga samayn karaa alaab tayo sare leh oo ceramik ah, 92 ~ 97% alumina, 99.5% alumina,> 99.9% alumina, iyo CIP qabow cadaadis isostatic. Heerkulka sare ee sintering iyo makiinada saxda ah, saxnaanta cabbirka ± 0.001mm, siman ilaa Ra0.1, isticmaal heerkulka ilaa 1600 darajo. Midabada kala duwan ee ceramics ayaa la samayn karaa iyadoo loo eegayo shuruudaha macaamiisha, sida: madow, caddaan, beige, casaan madow, iwm. Qaybaha dhoobada saxda ah ee ay soo saartay shirkadeena waxay u adkeysanayaan heerkulka sare, daxalka, xirashada iyo dahaarka, waxaana loo isticmaali karaa waqti dheer heerkulka sare, vacuum iyo deegaanka gaaska daxalka ah.

Si ballaaran loo isticmaalo noocyo kala duwan oo qalabka wax soo saarka semiconductor: Frames (bracket dhoobada), Substrate (saldhig), Arm / Bridge (manipulator), , Qaybaha makaanikada iyo Ceramic Air Bearing.

| Magaca Alaabta | Nadiifnimada Sare 99 Alumina Ceramic Square Tube / Dhuumaha / Usha | |||||

| Tusmada | Unug | 85% Al2O3 | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | |

| Cufnaanta | g/cm3 | 3.3 | 3.65 | 3.8 | 3.9 | |

| Nuugista Biyaha | % | <0.1 | <0.1 | 0 | 0 | |

| Heerkulka Sintered | ℃ | 1620 | 1650 | 1800 | 1800 | |

| Adag | Mohs | 7 | 9 | 9 | 9 | |

| Xoog Laabashada(20℃)) | Mpa | 200 | 300 | 340 | 360 | |

| Xoog isku dhejisan | Kgf/cm2 | 10000 | 25000 | 30000 | 30000 | |

| Heerkulka Shaqada Wakhti Dheer | ℃ | 1350 | 1400 | 1600 | 1650 | |

| Max. Heerkulka shaqada | ℃ | 1450 | 1600 | 1800 | 1800 | |

| Iska caabbinta mugga | 20℃ | Ω cm3 | >1013 | >1013 | >1013 | >1013 |

| 100 ℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300 ℃ | >109 | >1010 | >1012 | >1012 | ||

Codsiga dhoobada aluminium ee nadiifka sare ah:

1. Codsaday qalabka semiconductor: dhoobada vacuum chuck, saxanka goynta, saxanka nadiifinta, dhoobada CHUCK.

2. Qaybaha xawilaadda wafer-ka: maraqa wax-ka-qabashada ee wafer-ka, saxannada wafer-ka-goynta, saxannada wax lagu nadiifiyo ee wafer, koobabka wax-soo-saarka ee isha ee wafer.

3. LED / LCD warshadaha soo bandhig flat flat: biibiile dhoobada, saxan shiidi dhoobada, LIFT PIN, biin birta.

4. Isgaadhsiinta indhaha, warshadaha qoraxda: tuubooyinka dhoobada, dhoobada dhoobada, muraayadaha shaashadda daabacaadda dhoobada dhoobada.

5. Qaybaha kulaylka u adkaysta iyo korantada: dhoobada dhoobada.

Waqtigan xaadirka ah, ceramics aluminium oxide waxaa loo qaybin karaa nadiif sare iyo dhoobo caadi ah. Taxanaha dhoobada aluminium oksaydh ee nadiifka ah ee sarreeya waxa loola jeedaa walxaha dhoobada ah ee ka kooban in ka badan 99.9% Al₂O₃. Sababtoo ah heerkulkeeda qulqulaya ee ilaa 1650 - 1990 ° C iyo hirarka gudbinta ee 1 ~ 6μm, waxaa badanaa lagu farsameeyaa galaas isku dhafan halkii laga heli lahaa platinum crucible: kaas oo loo isticmaali karo sida tuubada sodium sababtoo ah gudbinta iftiinka iyo iska caabbinta daxalka ee birta alkali. Warshadaha elektiroonigga ah, waxa loo isticmaali karaa sida walxaha dahaadhka ah ee soo noqnoqda ee substrates IC. Sida laga soo xigtay waxyaabaha kala duwan ee aluminium oksaydh, taxanaha aluminium oxide dhoobada caadiga ah waxaa loo qaybin karaa 99 dhoobada, 95 dhoobada, 90 dhoobada iyo 85 dhoobada. Mararka qaarkood, ceramics-ka leh 80% ama 75% ee aluminium oxide ayaa sidoo kale loo kala saaraa sida taxanaha dhoobada aluminium oxide ee caadiga ah. Waxaa ka mid ah, 99 aluminium oxide dhoobada ah ayaa loo isticmaalaa in lagu soo saaro qolof heerkul sare leh, tuubada foornada dabka ka ilaalisa iyo walxaha gaarka ah ee u adkaysta, sida xirmooyinka dhoobada, shaabada dhoobada iyo taarikada valve. 95 ceramics aluminium ayaa inta badan loo isticmaalaa sidii qayb u adkaysata daxalka. 85 ceramics ayaa inta badan lagu qaso guryaha qaarkood, taaso kor u qaadaysa waxqabadka korantada iyo xoogga farsamada. Waxay isticmaali kartaa molybdenum, niobium, tantalum iyo bir kale oo shaabadood ah, qaarna waxaa loo isticmaalaa qalab koronto ah.

| Shayga Tayada (Qiimaha Wakiilka) | Magaca Alaabta | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Halabuurka Kiimikada Low-Sodium Alaabta Siinta Fudud | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| lol | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Dhexroorka Qayb Dhexdhexaad ah (MT-3300, habka falanqaynta laysarka) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| Cabbirka Crystal | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Samaynta Cufnaanta** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Cufnaanta Sintering** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Heerka hoos u dhaca ee khadka Sintering** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO kuma jirto xisaabinta daahirsanaanta Al₂O₃.

* Ma jiro budada wax-qabashada 29.4MPa (300kg/cm²), heerkulku waa 1600°C.

AES-11 / 11C / 11F: Ku dar 0.05 ~ 0.1% MgO, sinterability-ku waa mid aad u fiican, marka waxay khuseysaa ceramics aluminium oxide oo nadiif ah in ka badan 99%.

AES-22S: Lagu garto cufnaanta samaynta sare iyo heerka hoos u dhaca ee khadka sintering, waa lagu dabaqi karo simbiriirixan qaab shubista iyo alaabooyin kale oo waaweyn oo leh saxnaanta cabbirka loo baahan yahay.

AES-23 / AES-31-03: Waxay leedahay cufnaanta samaynta sare, thixotropy iyo viscosity hoose marka loo eego AES-22S. kii hore waxaa loo isticmaalaa dhoobada halka kan dambe loo isticmaalo biyo yareeyaha alaabta dabka, helitaanka caan.

Astaamaha Silicon Carbide (SiC)

| Tilmaamaha Guud | Nadiifinta qaybaha muhiimka ah (wt%) | 97 | |

| Midabka | Madow | ||

| Cufnaanta (g/cm³) | 3.1 | ||

| nuugista biyaha (%) | 0 | ||

| Tilmaamaha Makaanikada | Xoog dabacsanaan (MPa) | 400 | |

| Hababka dhalinyarada (GPa) | 400 | ||

| Vickers hardness (GPa) | 20 | ||

| Tilmaamaha kulaylka | Heerkulka shaqada ee ugu badan (°C) | 1600 | |

| Isku xidhka balaadhinta kulaylka | RT~500°C | 3.9 | |

| (1/°C x 10-6) | RT~800°C | 4.3 | |

| Dhaqdhaqaaqa kulaylka (W/m x K) | 130 110 | ||

| Iska caabbinta shoogga kulaylka ΔT (°C) | 300 | ||

| Tilmaamaha Korontada | Iska caabin mugga | 25°C | 3 x 106 |

| 300°C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Dielectric joogto ah | 10GHz | - | |

| Waayida korontada (x 10-4) | - | ||

| Qodobka Q (x 104) | - | ||

| Korantada burburka Dielectric (KV/mm) | - | ||

♦Silicon Nitride Ceramic

| Qalab | Unug | Si₃N₄ |

| Habka Sintering | - | Cadaadiska Gaaska ayaa sitay |

| Cufnaanta | g/cm³ | 3.22 |

| Midabka | - | Cawlan madow |

| Heerka Nuugista Biyaha | % | 0 |

| Modulus yar | Gpa | 290 |

| Vickers Hardness | Gpa | 18 - 20 |

| Xoog isku dhejisan | Mpa | 2200 |

| Xoog Laabashada | Mpa | 650 |

| Habdhaqanka kulaylka | W/mK | 25 |

| Iska caabinta shoogga kulaylka | Δ (°C) | 450 - 650 |

| Heerkulka shaqada ee ugu badan | °C | 1200 |

| Iska caabbinta mugga | Ω·cm | > 10 ^ 14 |

| Dielectric Constant | - | 8.2 |

| Xoogga Dielectric | kV/mm | 16 |