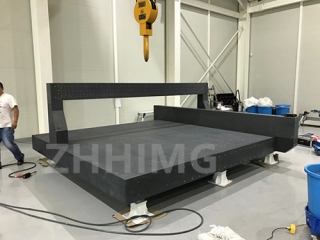

Isku-darka granite-ka saxda ah waxaa loola jeedaa habka wax-soo-saarka oo ku lug leh isticmaalka qaybaha granite-ka si taxaddar leh loo jaray oo loo hagaajiyay kuwaas oo loo isticmaalo isu-geynta aaladaha kala duwan. Isku-darka granite-ka saxda ah wuxuu leeyahay codsiyo kala duwan, oo ay ku jiraan horumarinta alaabada qalabka kormeerka ee looxyada LCD.

Alaabooyinka Qalabka Kormeerka Guddiyada LCD:

Badeecadaha qalabka kormeerka ee looxa LCD waa aalado elektaroonik ah oo loo isticmaalo xakamaynta tayada ee looxa bandhigga kiristaalka dareeraha ah (LCD). Waxay gacan ka geystaan sidii loo ogaan lahaa cillado kala duwan sida pixels-ka gubanaya iyo kuwa dhintay, hubinta soo saarista midabka saxda ah, iyo dhalaalka ugu fiican. Isku-darka granite-ka saxda ah ayaa kacaan ku sameeyay horumarinta aaladaha noocaas ah, iyadoo si weyn u wanaajisay shaqadooda, iyo tayada looxa LCD-ga ay baaraan.

Codsiyada Qalabka Granite-ka Sax ah ee Horumarinta Qalabka Kormeerka Guddiyada LCD:

1. Heerka Saxnaanta:

Qaybaha Granite-ka waxaa loo isticmaalaa in lagu abuuro dusha fidsan oo lagu dhejiyo muraayadaha LCD inta lagu jiro kormeerka, taasoo hubinaysa in si sax ah oo sax ah loo hagaajiyo. Qaybaha granite-ka ee loo isticmaalo tan waxaa si fiican loogu farsameeyay si loo gaaro saxnaan iyo xasillooni sare, taas oo damaanad qaadaysa saxnaanta sare ee kormeerka.

2. Xasilloonida iyo Waarta:

Qaybaha Granite-ka ayaa ka mid ah agabka ugu xasilloon uguna waara ee loo isticmaalo qodobka saxda ah ee qalabka kormeerka guddiga LCD. Waxay bixiyaan goob ka hortagta gariirka qalabka kormeerka, taas oo damaanad qaadaysa saxnaanta iyo kor u qaadida waxqabadka. Xasilloonida qaybaha Granite-ka ayaa si weyn u yareysa kharashyada dayactirka qalabka waxayna u oggolaanaysaa soo saarista aaladaha saxda ah ee u adkeysan kara xaaladaha adag iyo deegaanka.

3. Xasiloonida Kulaylka:

Mid ka mid ah astaamaha gaarka ah ee qaybaha granite-ka ayaa ah inay leeyihiin xasillooni kuleyl oo heer sare ah. Astaantan ayaa ka dhigaysa kuwo ku habboon in loo isticmaalo soo saarista aaladaha kormeerka guddiga LCD-ga maadaama ay si fiican u shaqeeyaan xitaa marka ay la kulmaan kala duwanaansho heerkulka deegaanka ah. Xasiloonida kulaylka ee ay bixiyaan qaybaha isku-dhafka granite-ka ee saxda ah waxay hubineysaa in guddiyada LCD-ga lagu baaro xaaladaha heerkulka ugu fiican, sidaas darteedna lagu gaaro saxnaanta ugu badan iyo soo saarista alaabada ugu fiican, tayada sare leh.

4. Heerarka Kala-hagaajinta Tayada Sare leh:

Qaybaha isku-darka granite-ka saxda ah waxaa loo isticmaalaa in lagu horumariyo heerarka cabbiraadda ee loo isticmaalo soo saarista alaabada qalabka kormeerka guddiga LCD. Heerarka cabbiraadda tayada sare leh waxay dammaanad qaadayaan in qalabku uu buuxiyo heerarka ugu saxsan, saxnaanta, iyo xasilloonida ee looga baahan yahay buuxinta baahiyaha suuqa ee muraayadaha LCD-ga tayada sare leh.

5. Khalad la dhimay:

Khaladaadka ku jira qalabka kormeerka guddiga LCD-ga waxay leeyihiin cawaaqib xumo weyn maadaama ay horseedi karaan soo saarista boqolaal guddi LCD ah oo cilladaysan. Qaybaha isku-dubaridka granite-ka saxda ah ayaa si taxaddar leh loo sameeyay si loo yareeyo heerka qaladka inta lagu jiro qalabka, sidaas darteedna waxay hagaajinayaan saxnaanta iyo saxnaanta kormeerka.

6. Wax soo saar la xoojiyay:

Qaybaha isku-dhafka granite-ka ee saxda ah waxay horumariyaan wax-soo-saarka qalabka kormeerka guddiga LCD-ga. Waxay u oggolaanayaan soo saarista aalado adag, deggan, iyo kuwo lagu kalsoonaan karo oo sameeya kormeer degdeg ah oo sax ah. Waxqabadka sare ee qaybaha isku-dhafka granite-ka ee saxda ah waxay dammaanad qaadayaan tayada guddiga LCD-ga ee ugu wanaagsan, taas oo yaraynaysa waqtiga wax soo saarka iyo khasaaraha agabka.

Gunaanad:

Marka la soo koobo, isku-darka granite-ka saxda ah wuxuu door muhiim ah ka ciyaaraa horumarinta alaabada qalabka kormeerka guddiga LCD-ga ee tayada sare leh. Waxay bixisaa saxnaanta iyo saxnaanta lagama maarmaanka ah ee loo baahan yahay si loo soo saaro guddiyada LCD-ga ee tayada sare leh, sidaas darteedna waxay hagaajinaysaa tayada guud ee nolosha. Adeegsiga isku-darka granite-ka saxda ah ee soo saarista aaladaha kormeerka guddiga LCD waxay bixiyaan fursado cusub mustaqbalka tignoolajiyadan, taas oo sii wadata inay ka faa'iidaysato warshadaha wax soo saarka elektaroonigga ah guud ahaan.

Waqtiga boostada: Noofambar-06-2023