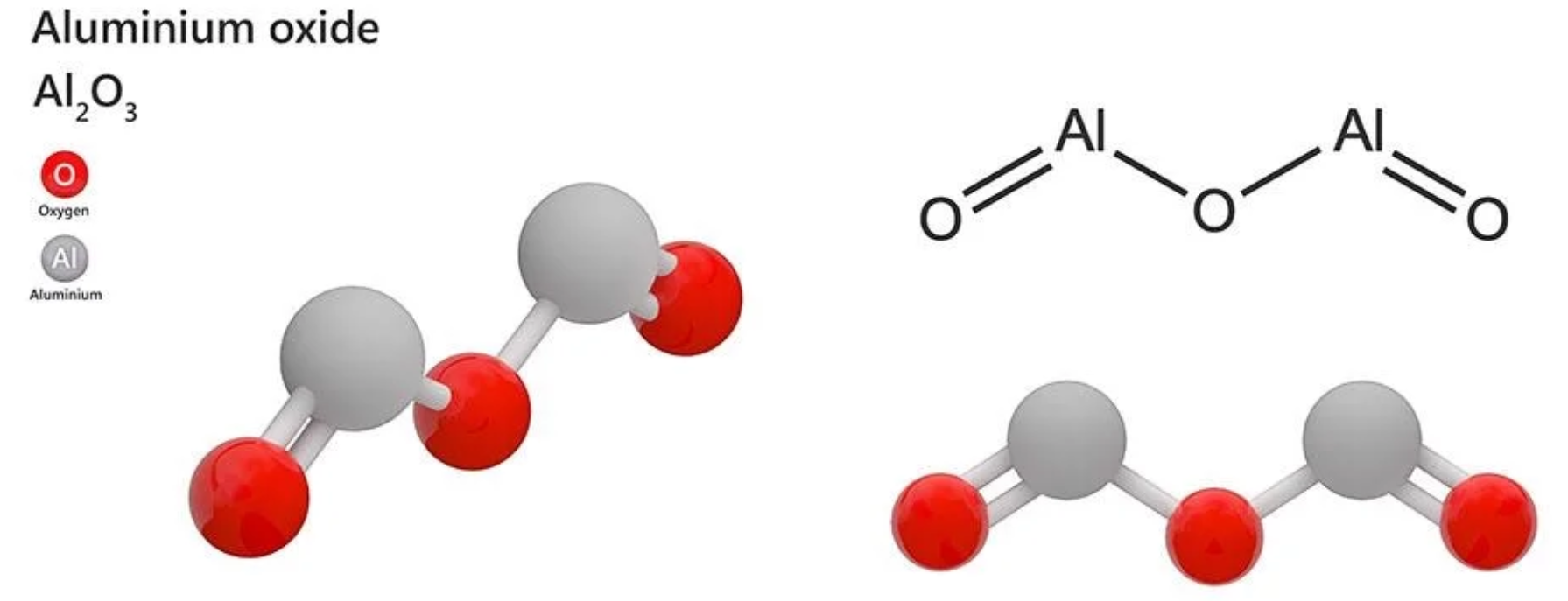

♦Alumina (Al)2O3)

Qaybaha dhoobada saxda ah ee ay soo saarto ZhongHui Intelligent Manufacturing Group (ZHHIMG) waxaa laga samayn karaa walxo ceeriin ah oo ceeriin ah oo saafi ah, 92 ~ 97% alumina, 99.5% alumina, > 99.9% alumina, iyo cadaadiska isostatic qabow ee CIP. Sintering heerkulka sare iyo mashiinka saxda ah, saxnaanta cabbirka ± 0.001mm, simanaanta ilaa Ra0.1, isticmaal heerkulka ilaa 1600 digrii. Midabada kala duwan ee dhoobada waxaa lagu samayn karaa iyadoo loo eegayo shuruudaha macaamiisha, sida: madow, caddaan, beige, casaan madow, iwm. Qaybaha dhoobada saxda ah ee ay soo saarto shirkaddayadu waxay u adkaystaa heerkulka sare, miridhka, xirashada iyo dahaarka, waxaana loo isticmaali karaa muddo dheer jawiga gaaska ee heerkulka sare, faakiyuumka iyo daxalka.

Waxaa si ballaaran loogu isticmaalaa qalabka wax soo saarka semiconductor-ka kala duwan: Frames (qalabka dhoobada ah), Substrate (saldhigga), Gacan/Buundada (manipulator), Qaybaha Farsamada iyo Hawada Dhoobada ah.

| Magaca Badeecada | Nadiifnimo Sare 99 Alumina Ceramic Square Tube / Tuubo / Usha | |||||

| Tusmada | Cutubka | 85% Al2O3 | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | |

| Cufnaanta | g/cm3 | 3.3 | 3.65 | 3.8 | 3.9 | |

| Nuugista Biyaha | % | <0.1 | <0.1 | 0 | 0 | |

| Heerkulka Nadiifsan | ℃ | 1620 | 1650 | 1800 | 1800 | |

| Adkaanta | Mohs | 7 | 9 | 9 | 9 | |

| Xoog Laabista (20℃)) | Mpa | 200 | 300 | 340 | 360 | |

| Xoog Cadaadis ah | Kgf/cm2 | 10000 | 25000 | 30000 | 30000 | |

| Heerkulka Shaqada ee Muddada Dheer | ℃ | 1350 | 1400 | 1600 | 1650 | |

| Heerkulka ugu badan ee Shaqada | ℃ | 1450 | 1600 | 1800 | 1800 | |

| Iska caabinta Mugga | 20℃ | Ω. cm3 | >1013 | >1013 | >1013 | >1013 |

| 100℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300℃ | >109 | >1010 | >1012 | >1012 | ||

Adeegsiga dhoobada aluminium ee saafiga ah oo heer sare ah:

1. Waxaa lagu dabaqay qalabka semiconductor-ka: qalabka faakiyuumka dhoobada ah, saxanka jarista, saxanka nadiifinta, CHUCK dhoobada ah.

2. Qaybaha wareejinta Wafer-ka: chucks-ka maaraynta Wafer-ka, saxannada jarista Wafer-ka, saxannada nadiifinta Wafer-ka, koobabka nuugista kormeerka indhaha ee Wafer-ka.

3. Warshadaha bandhigga LED / LCD ee fidsan: afka dhoobada, saxanka shiidi dhoobada, PIN LIFT, rail PIN.

4. Isgaarsiinta indhaha, warshadaha qorraxda: tuubooyinka dhoobada, ulaha dhoobada, daabacaadda shaashadda looxa wareegyada xoqidda dhoobada.

5. Qaybaha u adkaysta kulaylka iyo korontada: biinanka dhoobada ah.

Waqtigan xaadirka ah, dhoobada aluminium oksaydhka waxaa loo qaybin karaa daahirnimo sare iyo dhoobo caadi ah. Taxanaha dhoobada aluminium oksaydhka saafiga ah ee sare waxaa loola jeedaa walxaha dhoobada ah ee ka kooban in ka badan 99.9% Al₂O₃. Sababtoo ah heerkulkeeda sintering-ka ilaa 1650 - 1990°C iyo hirarka gudbinta ee 1 ~ 6μm, badanaa waxaa loo farsameeyaa galaas isku dhafan halkii laga isticmaali lahaa platinum crucible: kaas oo loo isticmaali karo tuubo sodium ah sababtoo ah gudbinta iftiinka iyo iska caabbinta daxalka ee birta alkali. Warshadaha elektaroonigga ah, waxaa loo isticmaali karaa sidii walxo dahaadh sare leh oo loogu talagalay substrate-ka IC. Sida laga soo xigtay waxyaabaha kala duwan ee aluminium oksaydhka, taxanaha dhoobada aluminium oksaydhka caadiga ah waxaa loo qaybin karaa 99 dhoobo, 95 dhoobo, 90 dhoobo iyo 85 dhoobo. Mararka qaarkood, dhoobada leh 80% ama 75% oo ah aluminium oksaydhka ayaa sidoo kale loo kala saaraa taxane dhoobo aluminium oksaydh caadi ah. Waxaa ka mid ah 99 walxo dhoobada aluminium oksaydh ah ayaa loo isticmaalaa in lagu soo saaro tuubo foorno oo heerkul sare leh oo dab-damis ah iyo walxo gaar ah oo u adkaysta xirashada, sida boodhadhka dhoobada, shaabaddaha dhoobada iyo saxannada waalka. 95 dhoobo aluminium ah ayaa inta badan loo isticmaalaa qayb ka mid ah xirashada iska caabbinta daxalka. 85 dhoobo ayaa badanaa lagu qasi karaa sifooyin qaar, taasoo hagaajinaysa waxqabadka korontada iyo xoogga farsamada. Waxay isticmaali kartaa molybdenum, niobium, tantalum iyo shaabad kale oo bir ah, qaarna waxaa loo isticmaalaa qalab faakiyuum koronto ah.

| Shay Tayo leh (Qiimaha Wakiilnimada) | Magaca Badeecada | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Halabuurka Kiimikada Badeeco Sifeyn Fudud oo Sodium Yar leh | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| LOl | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Dhexroorka Walxaha Dhexdhexaadka ah (MT-3300, habka falanqaynta laysarka) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| α Cabbirka Kiristariga | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Cufnaanta Samaynta** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Cufnaanta Sintering** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Heerka Hoos u dhaca ee Khadka Sintering** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO kuma jiraan xisaabinta daahirnimada Al₂O₃.

* Budada cabbirka ma laha 29.4MPa (300kg/cm²), heerkulka sintering-ku waa 1600°C.

AES-11 / 11C / 11F: Ku dar 0.05 ~ 0.1% MgO, sinterability-gu waa mid aad u fiican, sidaa darteed waxaa lagu dabaqi karaa dhoobada aluminium oksaydhka oo leh daahirnimo ka badan 99%.

AES-22S: Waxaa lagu gartaa cufnaanta sameynta sare iyo heerka hoos u dhaca khadka sintering-ka, waxaa lagu dabaqi karaa shubka qaabka simbiriirixan iyo alaabada kale ee baaxadda weyn leh ee saxnaanta cabbirka loo baahan yahay.

AES-23 / AES-31-03: Waxay leedahay cufnaan ka sarreysa qaab-dhismeedka, thixotropy iyo viscosity ka hooseeya AES-22S. kan hore waxaa loo isticmaalaa dhoobada halka kan dambe loo isticmaalo sidii biyo-yareeye loogu talagalay agabka dabka ka ilaaliya, taasoo caan ka dhigaysa.

♦ Astaamaha Silicon Carbide (SiC)

| Astaamaha Guud | Nadiifnimada qaybaha ugu muhiimsan (wt%) | 97 | |

| Midab | Madow | ||

| Cufnaanta (g/cm³) | 3.1 | ||

| Nuugista biyaha (%) | 0 | ||

| Astaamaha Farsamada | Xoogga dabacsanaanta (MPa) | 400 | |

| Modulus-ka Da'da Yar (GPa) | 400 | ||

| Adkaanshaha Vickers (GPa) | 20 | ||

| Astaamaha Kulaylka | Heerkulka ugu badan ee hawlgalka (°C) | 1600 | |

| Heerka ballaarinta kulaylka | RT~500°C | 3.9 | |

| (1/°C x 10-6) | RT~800°C | 4.3 | |

| Gudbinta kulaylka (W/m x K) | 130 110 | ||

| Iska caabbinta shoogga kulaylka ΔT (°C) | 300 | ||

| Astaamaha Korontada | Iska caabinta mugga | 25°C | 3 x 106 |

| 300°C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Joogtada Dielectric | 10GHz | - | |

| Lumitaanka Dielectric (x 10-4) | - | ||

| Q Factor (x 104) | - | ||

| Danabka burburka dielectric (KV/mm) | - | ||

♦Silicon Nitride Dhoobada

| Alaab | Cutubka | Si₃N₄ |

| Habka Sintering | - | Cadaadiska Gaaska oo la sifeeyay |

| Cufnaanta | g/cm³ | 3.22 |

| Midab | - | Cawlan Madow |

| Heerka nuugista biyaha | % | 0 |

| Modulus-ka Da'da yar | GPA | 290 |

| Adkaanshaha Vickers | GPA | 18 - 20 |

| Xoog Cadaadis ah | Mpa | 2200 |

| Xoog Laabista | Mpa | 650 |

| Qaboojinta Kulaylka | W/mK | 25 |

| Iska caabinta Shoogga Kulaylka | Δ (°C) | 450 - 650 |

| Heerkulka Hawlgalka Ugu Badan | °C | 1200 |

| Iska caabinta Mugga | Ω·cm | > 10 ^ 14 |

| Joogtada Dielectric | - | 8.2 |

| Xoogga Dielectric | kV/mm | 16 |