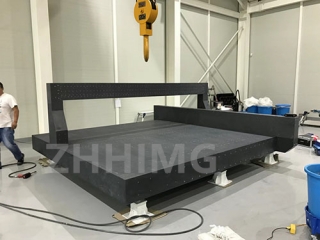

Madal sax ah oo granite ah ayaa door muhiim ah ka ciyaarta mashiinka feerka ee looxa wareegga PCB waana saldhigga hawlgalka oo dhan. Madal sax ah waxaa laga sameeyay granite tayo sare leh si loo helo xasillooni sare, cimri dherer iyo iska caabin xirasho. Doorkeeda mashiinnada feerka ee looxa wareegga PCB waa mid dhinacyo badan leh oo muhiim u ah helitaanka natiijooyin sax ah.

Marka ugu horreysa uguna muhiimsan, madal sax ah oo granite ah waxay bixisaa dusha sare oo deggan oo siman oo loogu talagalay mashiinka feeraha guddiga wareegga PCB. Xasilloonidani waa mid muhiim u ah hubinta in mashiinku si sax ah u shaqeeyo, maadaama gariir kasta ama dhaqdhaqaaq kasta uu sababi karo khaladaad inta lagu jiro habka shaambadda. Adkaanta madal granite waxay gacan ka geysaneysaa yareynta leexashada ama isbeddelka suurtagalka ah inta lagu jiro hawlgalka shaambadda, taasoo ilaalinaysa sharafta guddiga wareegga.

Intaa waxaa dheer, madal sax ah oo granite ah waxay u adeegtaa sidii dusha tixraaca ee loogu talagalay meelaynta iyo isku-dubaridka looxa inta lagu jiro habka shaabadaynta. Fidsanaanta iyo simanaanta dusha sare ee granite waxay u oggolaanaysaa meelaynta saxda ah ee looxa wareegga, iyadoo la hubinayo in qalabka feerka si sax ah loogu beegsado meesha loo qoondeeyay iyada oo aan wax leexasho ah lahayn. Heerkan saxnaanta ah ayaa muhiim u ah ilaalinta tayada iyo hufnaanta qaab-dhismeedka iyo naqshadeynta looxa wareegga.

Intaa waxaa dheer, xasilloonida kulaylka ee madal saxnaanta granite-ka ayaa muhiim u ah mashiinnada feeraha ee looxyada wareegga PCB. Granite-ku wuxuu leeyahay ballaarin kuleyl oo yar, taasoo la macno ah inuu si cabbir ahaan u deggan yahay xitaa marka la mariyo isbeddellada heerkulka. Astaantan ayaa muhiim u ah hubinta waxqabadka saxaafadda ee joogtada ah oo la isku halleyn karo, gaar ahaan deegaannada ay isbeddellada heerkulku ka dhici karaan.

Gunaanadkii, madal saxnaanta granite-ka ayaa door muhiim ah ka ciyaarta mashiinnada feerka ee looxa wareegga PCB iyadoo bixinaysa xasillooni, saxnaan iyo xasillooni kuleyl. Dhismaheeda adag iyo waxqabadkeeda sare waxay ka dhigayaan qayb lama huraan ah habka wax soo saarka PCB si loo helo natiijooyin sax ah oo tayo sare leh. Maadaama tignoolajiyadu ay sii socoto, doorka aaladaha saxda ah ee granite-ka ee mashiinnada feerka ee looxa wareegga PCB ayaa weli ah qayb muhiim ah oo ka mid ah soo saarista looxyada wareegga ee la isku halleyn karo oo hufan.

Waqtiga boostada: Luulyo-03-2024