Qaybaha Saxnaanta Granite: Arrimaha ay tahay in la tixgeliyo marka la isku darayo Mashiinka VMM

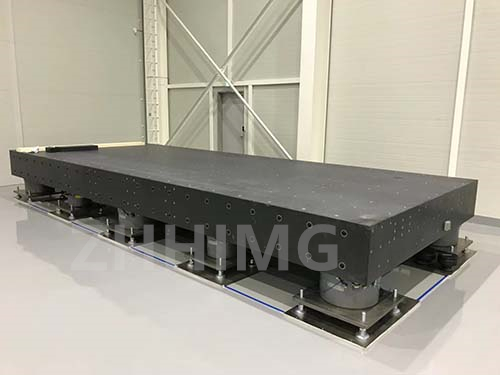

Marka ay timaado isku-darka qaybaha saxda ah ee granite-ka mashiinka VMM (Mashiinka Cabbirka Aragtida), dhowr arrimood ayaa loo baahan yahay in si taxaddar leh looga fiirsado si loo hubiyo waxqabadka ugu wanaagsan iyo saxnaanta. Granite waa doorasho caan ah oo loogu talagalay qaybaha saxda ah sababtoo ah xasilloonideeda cabbirka ee aadka u wanaagsan, adkaanta sare, iyo iska caabbinta xirashada iyo daxalka. Si kastaba ha ahaatee, si buuxda looga faa'iidaysto faa'iidooyinka granite-ka mashiinka VMM, arrimaha soo socda waa in la tixgeliyaa:

1. Tayada Agabka: Tayada granite-ka loo isticmaalo qaybaha saxda ah waa muhiim. Granite tayo sare leh oo leh cufnaan isku mid ah iyo cadaadis gudaha ah oo yar ayaa lagama maarmaan u ah in la gaaro cabbiro sax ah oo la isku halleyn karo oo ku jira mashiinka VMM.

2. Xasiloonida Kulaylka: Xasiloonida kulaylka ee Granite waa tixgelin muhiim ah, maadaama isbeddelka heerkulku uu saameyn karo saxnaanta cabbirka ee qaybaha. Waa muhiim in la doorto granite leh sifooyin ballaarin kuleyl oo hooseeya si loo yareeyo saameynta kala duwanaanshaha heerkulka ee waxqabadka mashiinka.

3. Astaamaha Adkaanta iyo Daadinta: Astaamaha adkeysiga iyo daadinta ee qaybaha granite-ka ayaa door muhiim ah ka ciyaara yaraynta gariirka iyo hubinta cabbiraadaha deggan. Isku-darka granite-ka oo leh adkeysi sare iyo astaamo daadin heer sare ah ayaa kor u qaadi kara saxnaanta guud iyo ku celcelinta mashiinka VMM.

4. Dhammaystirka Dusha Sare iyo Fidsanaanta: Dhammaystirka dusha sare iyo fidsanaanta qaybaha granite-ka ayaa muhiim u ah gaaritaanka cabbirrada saxda ah. Waa in fiiro gaar ah loo yeesho hababka wax soo saarka si loo hubiyo in dusha sare ee granite-ku ay siman yihiin, siman yihiin, oo ka xor yihiin cillado waxyeellayn kara saxnaanta mashiinka VMM.

5. Ku rakibidda iyo Isku-dubaridka: Ku rakibidda iyo isku-dubaridka saxda ah ee qaybaha saxda ah ee granite-ka ee ku jira mashiinka VMM ayaa lagama maarmaan u ah ilaalinta hufnaanta cabbiraadaha. Farsamooyinka ku rakibidda saxda ah iyo hababka isku-dubaridka taxaddar leh waa in la adeegsadaa si loo hubiyo in qaybaha granite-ku si habsami leh ugu shaqeeyaan gudaha mashiinka.

6. Tixgelinta Deegaanka: Deegaanka hawlgalka ee mashiinka VMM waa in la tixgeliyaa marka la isku darayo qaybaha saxda ah ee granite. Arrimaha sida xakamaynta heerkulka, heerarka qoyaanka, iyo soo-gaadhista wasakhda waa in la maareeyaa si loo ilaaliyo xasilloonida cabbirka iyo waxqabadka qaybaha granite-ka.

Gunaanad ahaan, ku darista qaybaha saxda ah ee granite mashiinka VMM waxay u baahan tahay fiiro gaar ah oo ku saabsan tayada agabka, xasilloonida kulaylka, adkaanta, dhammaystirka dusha sare, rakibidda, isku-dubaridka, iyo arrimaha deegaanka. Iyagoo wax ka qabanaya tixgelinnadan, soosaarayaashu waxay hagaajin karaan waxqabadka iyo saxnaanta mashiinadooda VMM, ugu dambayntiina waxay kor u qaadayaan tayada iyo isku halaynta hababka cabbiraadda.

Waqtiga boostada: Luulyo-02-2024