Granite waa nooc ka mid ah dhagaxa dabiiciga ah oo si weyn loogu isticmaalo codsiyo kala duwan sababtoo ah sifooyinkiisa iyo sifooyinkiisa gaarka ah. Waaradiisa, iska caabintiisa xirashada iyo jeexjeexa, iyo iska caabbinta kiimikooyinka ayaa ka dhigaya agab ku habboon soo saarista qalabka saxda ah. Mid ka mid ah codsiyada noocaas ah ee granite waa alaabada qalabka kormeerka guddiga LCD. Maqaalkan, waxaan ka hadli doonnaa meelaha kala duwan ee loo adeegsado qalabka kormeerka guddiga LCD ee ku salaysan granite.

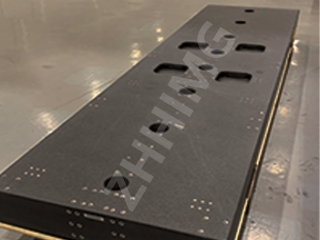

Qalabka kormeerka ee looxa LCD-ga waxaa loo isticmaalaa in lagu hubiyo tayada iyo isku dheelitirka shaashadaha LCD-ga ee loo isticmaalo aaladaha elektaroonigga ah ee kala duwan. Qalabkan waxaa loo isticmaalaa habka wax soo saarka si loo hubiyo in shaashad kastaa ay buuxiso heerarka iyo qeexitaannada qaarkood. Qalabku wuxuu ka kooban yahay qaybo kala duwan oo si wada jir ah u shaqeeya si loo baaro shaashadaha LCD-ga. Mid ka mid ah qaybaha ugu muhiimsan ee qalabkan waa saldhigga, kaas oo laga sameeyay granite.

Isticmaalka granite-ka oo ah agab saldhig u ah qalabka kormeerka guddiga LCD wuxuu leeyahay faa'iidooyin dhowr ah. Marka hore, granite-ku waa walxo aad u deggan oo aan ballaarin ama isku dhicin sababtoo ah isbeddelka heerkulka ama qoyaanka. Tani waxay ka dhigaysaa agab ku habboon qalabka saxda ah, maadaama ay hubinayso in qalabku uu ilaaliyo saxnaantiisa iyo saxnaantiisa waqti ka dib. Marka labaad, granite-ku waa agab aad u adag oo iska caabiya xirashada iyo jeexitaanka, taasoo la macno ah in saldhigga qalabku uu sii jiri doono muddo dheer iyada oo aan loo baahnayn beddel. Ugu dambeyntii, granite-ku waa agab aan birlab ahayn, taasoo la macno ah inaysan faragelin doonin calaamadaha elektaroonigga ah ama birlabka inta lagu jiro habka wax soo saarka.

Mid ka mid ah meelaha ugu muhiimsan ee loo adeegsado qalabka kormeerka ee loo yaqaan 'granite panel' ee LCD-ga ku salaysan granite waa soo saarista aaladaha elektarooniga ah sida taleefannada casriga ah iyo kiniiniyada. Qalabkani wuxuu u baahan yahay shaashado LCD tayo sare leh oo joogto ah oo la isku halleyn karo. Isticmaalka aaladaha kormeerka ee ku salaysan granite waxay hubineysaa in shaashad kastaa ay buuxiso heerarka iyo tilmaamaha loo baahan yahay, taas oo gacan ka geysaneysa hagaajinta tayada guud ee badeecada.

Meel kale oo lagu dabaqo qalabka kormeerka LCD-ga ee ku salaysan granite waa soo saarista qalabka caafimaadka sida mashiinnada raajada iyo sawir-qaadayaasha ultrasound-ka. Qalabkani wuxuu u baahan yahay shaashado LCD oo sax ah oo ay tahay in la baaro oo la tijaabiyo si loo helo saxnaan iyo joogteyn. Isticmaalka aaladaha kormeerka ee ku salaysan granite waxay hubineysaa in shaashad kastaa ay buuxiso shuruudaha loo baahan yahay, taas oo gacan ka geysaneysa hagaajinta saxnaanta iyo isku halaynta qalabka caafimaadka.

Marka laga soo tago warshadaha wax soo saarka, aaladaha kormeerka ee ku salaysan granite LCD-ka ayaa sidoo kale loo isticmaalaa shaybaarrada cilmi-baarista iyo horumarinta. Qalabkan waxaa loo isticmaalaa in lagu tijaabiyo shaashadaha cusub ee LCD-ga iyo teknoolojiyada si loo hubiyo inay buuxiyaan heerarka iyo qeexitaannada loo baahan yahay. Isticmaalka aaladaha kormeerka ee ku salaysan granite waxay hubineysaa in natiijooyinka imtixaannadani ay yihiin kuwo sax ah oo la isku halleyn karo, taas oo gacan ka geysaneysa hagaajinta tayada alaabada mustaqbalka.

Gunaanadkii, aaladaha kormeerka ee looxa LCD-ga ee ku salaysan granite-ka waxay leeyihiin meelo badan oo lagu dabaqo warshado kala duwan. Isticmaalka granite-ka oo ah agab saldhig u ah aaladahaan waxay hubineysaa inay sax yihiin, la isku halleyn karo, oo waara yihiin, taasoo gacan ka geysaneysa hagaajinta tayada guud ee alaabada la soo saaro iyadoo la adeegsanayo aaladahaan. Hadday tahay soo saarista aaladaha elektaroonigga ah, qalabka caafimaadka, ama cilmi-baarista iyo horumarinta, aaladaha kormeerka ee ku salaysan granite-ka waxay door muhiim ah ka ciyaaraan hubinta in shaashadaha LCD ay buuxiyaan heerarka iyo qeexitaannada loo baahan yahay.

Waqtiga boostada: Noofambar-01-2023