Granite waa dhagax dabiici ah oo laga sameeyay qaboojinta iyo adkaynta magma-da foolkaanaha ama lava. Waa walax aad u cufan oo waara oo aad u adkaysata xoqidda, wasakhaynta, iyo kulaylka. Granite waxaa si weyn loogu isticmaalaa warshadaha dhismaha agabka dhismaha sida miisaska miiska, sagxadaha, iyo wajiyada sababtoo ah xooggeeda iyo cimrigeeda. Marka laga soo tago codsiyadan, granite waxay sidoo kale soo gashay warshadaha qalabka isku-dubaridka saxda ah, halkaas oo si weyn loogu isticmaalo agab saldhig ah.

Qalabka isku-dubaridka saxda ah waxaa loo isticmaalaa warshado kala duwan sida baabuurta, hawada sare, iyo caafimaadka, halkaas oo heerarka saxda ah ee saxnaanta iyo isku halaynta ay muhiim u yihiin. Qalab aasaasi ah ayaa looga baahan yahay aaladahaan oo bixin kara gariir aad u fiican, adkaansho sare, iyo xasillooni kuleyl. Granite waxay buuxisaa dhammaan shuruudahan, taasoo ka dhigaysa doorashada ugu habboon ee saldhigga qalabka isku-dubaridka saxda ah.

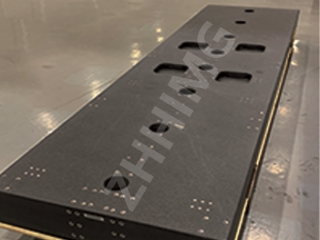

Mid ka mid ah codsiyada aasaasiga ah ee granite-ka ee qalabka isku-dubaridka saxda ah waa soo saarista mashiinnada cabbiraadda isku-dubaridka (CMMs). CMM-yada waxaa loo isticmaalaa warshadaha wax soo saarka si loo cabbiro cabbirka qaybaha ilaa heer sare oo sax ah. Mashiinnadani waxay isticmaalaan saldhig granite ah sababtoo ah waxay bixisaa goob deggan oo lagu kalsoonaan karo oo loogu talagalay nidaamka cabbirka. Granite-ku wuxuu leeyahay isku-darka aad u hooseeya ee ballaarinta kulaylka, taasoo la macno ah inay aad u adkeysanayso isbeddellada heerkulka. Tani waxay ka dhigaysaa agab ku habboon ilaalinta saxnaanta nidaamka cabbiraadda.

Granite sidoo kale si weyn ayaa loogu isticmaalaa soo saarista nidaamyada isku-xidhka indhaha. Nidaamyadan waxaa loo isticmaalaa in lagu hagaajiyo qaybaha indhaha si sax ah oo aad u sarreeya. Aaladda saldhigga granite waa lama huraan nidaamyadan sababtoo ah waxay bixisaa heer sare oo adkaansho ah, taas oo looga baahan yahay in la ilaaliyo isku-xidhka qaybaha indhaha. Granite sidoo kale aad ayuu u adkaysi badan yahay gariirka, taas oo ka dhigaysa mid ku habboon in loo isticmaalo deegaannada heerarka gariirku ay sarreeyaan, sida warshadaha wax soo saarka.

Adeegsiga kale ee granite-ka ee qalabka isku-dubaridka saxda ah waa soo saarista qalabka wax-soo-saarka semiconductor-ka. Soo-saarista semiconductor-ka waxay u baahan tahay heer sare oo sax ah si loo hubiyo in qaybaha loo soo saaro heerarka saxda ah. Saldhig granite ah wuxuu bixiyaa xasilloonida iyo adkaanta loo baahan yahay ee qalabka wax-soo-saarka, taas oo gacan ka geysaneysa hubinta in qaybaha loo soo saaro si waafaqsan shuruudaha loo baahan yahay.

Marka laga soo tago codsiyadan, granite waxaa sidoo kale loo isticmaalaa soo saarista qalabka shaybaarka, sida dheelitirka miisaanka iyo qalabka spectroscopy. Qalabkani wuxuu u baahan yahay heer sare oo xasillooni ah si loo hubiyo cabbiraadda saxda ah. Saldhig granite ah wuxuu bixiyaa xasilloonida iyo adkaanta loo baahan yahay ee loogu baahan yahay noocyadan qalabka, taasoo ka dhigaysa doorasho ku habboon.

Gunaanadkii, granite waa walax aad u badan oo si ballaaran loogu isticmaalo warshadaha injineernimada saxda ah. Sifooyinka adkaanta sare, yaraynta gariirka, iyo xasilloonida kulaylka ayaa ka dhigaya doorashada ugu habboon ee qalabka saldhigga ah ee qalabka isku-dubaridka saxda ah. Laga bilaabo CMMs ilaa qalabka wax soo saarka semiconductor-ka, granite waxay heshay adeegsiyo kala duwan, taasoo ka caawisa hubinta in aaladaha la soo saaray ilaa heerarka saxda ah ee saxnaanta iyo isku halaynta. Maadaama baahida loo qabo qaybaha saxda ah ay sii kordheyso, waxay u badan tahay in isticmaalka granite ee injineernimada saxda ah uu sii kordho.

Waqtiga boostada: Noofambar-21-2023