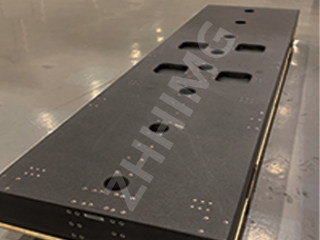

Granite waa dhagax dabiici ah oo leh xasillooni aad u fiican, ballaarin heerkul hooseeya, iyo adkeysi sare, taasoo ka dhigaysa doorasho loogu talagalay codsiyada warshadaha badan, oo ay ku jiraan alaabada farsamaynta laysarka. Iyadoo ay sii kordhayso baahida loo qabo mashiinnada iyo qalabka warshadaha ee saxnaanta sare leh, granite waxay noqotay agab caan ah oo loogu talagalay dhismaha saldhigyada mashiinnada iyadoo la kordhinayo saxnaanta cabbirka iyo xasilloonida, kuwaas oo lagama maarmaan u ah alaabada farsamaynta laysarka. Waa kuwan qaar ka mid ah meelaha loo adeegsado saldhigga granite ee alaabada farsamaynta laysarka:

1. Mashiinnada Jarista Laser-ka

Saxnaanta mashiinnada jarista laysarka ayaa muhiim u ah warshadaha wax soo saarka. Granite waa agab saldhig oo ku habboon mashiinnadan sababtoo ah waxay bixisaa xasillooni kuleyl oo aad u fiican, taasoo u suurtagelinaysa mashiinnada inay soo saaraan jaritaan siman oo sax ah. Isugeynteeda ballaarinta kulaylka oo hooseysa waxay hubisaa in saldhigga mashiinku uusan ballaarin ama uusan la qabsan kulaylka inta lagu jiro jarista laysarka, taasoo hubinaysa tayada jarista joogtada ah ee agabyada kala duwan.

2. Mashiinnada Qorista Laser-ka

Mashiinnada xaraashka laysarka waxaa loo isticmaalaa in lagu sameeyo naqshado sax ah oo ku yaal meelaha adag, sida birta, alwaaxa, iyo granite. Saxnaanta loo baahan yahay mashiinnadan ayaa granite ka dhigaysa agabka saldhigga ugu habboon maadaama ay hubinayso xasilloonida iyo iska caabbinta gariirka. Adkaanta granite waxay hubineysaa in saldhigga mashiinku uusan dhaqaaqin ama gariirin inta lagu jiro xaraashka, taasoo keenta naqshado sax ah oo sax ah.

3. Mashiinnada Calaamadaynta laysarka

Mashiinnada calaamadaynta laysarka waxaa loo isticmaalaa in lagu daro calaamado joogto ah oo ku yaal dusha sare ee kala duwan, oo ay ku jiraan biraha, balaastikada, iyo dhoobada. Granite waa agab la doorbido saldhigga mashiinka maadaama ay bixiso sifooyin qoyaan oo aad u fiican, taasoo yaraynaysa saameynta gariirka mashiinka inta lagu jiro isticmaalka. Xasilloonida granite waxay hubisaa dhaqdhaqaaq yar inta lagu jiro calaamadaynta, taasoo keenta calaamado sax ah oo sax ah.

4. Mashiinnada Alxanka Laser-ka

Mashiinnada alxanka laysarka waxaa loo isticmaalaa in lagu xidho agab kala duwan, oo ay ku jiraan biraha, balaastikada, iyo dhoobada. Saxnaanta loo baahan yahay mashiinnadan waxay ka dhigaysaa granite agab saldhig ku habboon. Ballaarinta kulaylka oo hooseysa iyo adkaanta sare waxay hubisaa xasilloonida iyo dhaqdhaqaaqa yar inta lagu jiro habka alxanka, taasoo hubinaysa saxnaanta iyo saxnaanta alxanka.

5. Mashiinnada Qodista Laser-ka

Mashiinnada qodista laysarka waxaa loo isticmaalaa in lagu abuuro godad sax ah oo ku yaal noocyo kala duwan oo agab ah, oo ay ku jiraan biraha iyo dhoobada. Saxnaanta loo baahan yahay mashiinnadan waxay ka dhigaysaa granite-ka agab saldhig oo qumman, iyadoo bixisa xasillooni cabbireed oo aad u fiican iyo isku-darka ballaarinta kulaylka oo hooseeya. Tani waxay hubinaysaa qodid sax ah oo leh qallooc yar ama dhaawac soo gaara agabka.

Gunaanadkii, saldhigga granite waa agab aad u fiican oo lagu dhiso saldhigyada mashiinka ee alaabada farsamaynta laysarka sababtoo ah xasilloonidiisa sare, adkaanta, iyo isku-darka ballaarinta kulaylka oo hooseeya. Saxnaanta iyo saxnaanta kordhay ee mashiinnadani waa lama huraan u ah codsiyada wax soo saarka warshadaha, taasoo ka dhigaysa granite agabka ugu habboon mashiinnadan. Natiijo ahaan, saldhigga granite wuxuu sii ahaan doonaa doorasho caan ah oo loogu talagalay alaabada farsamaynta laysarka ee warshadaha kala duwan.

Waqtiga boostada: Noofambar-10-2023