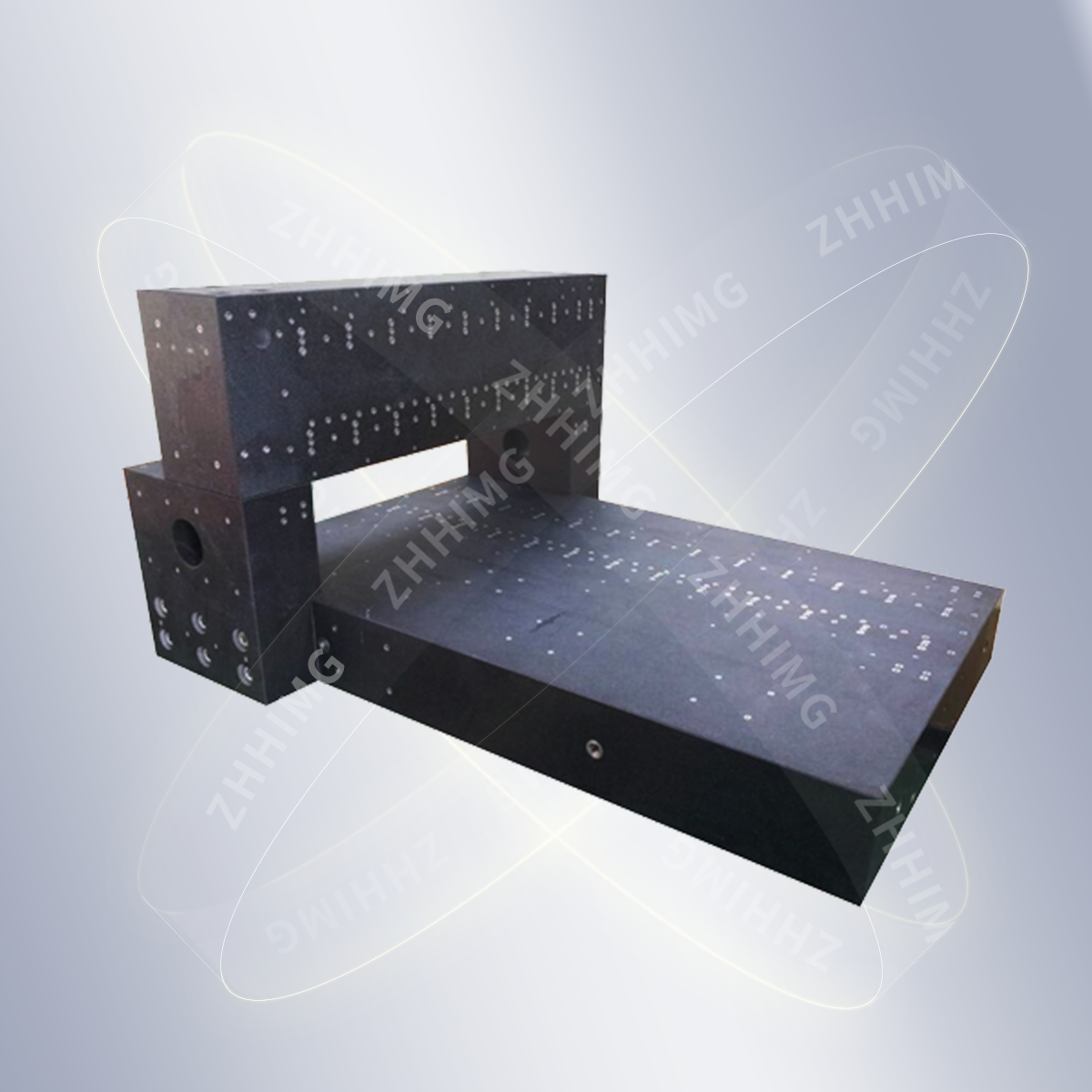

Dhinaca cabbirka saxda ah, saxnaanta cabbiraadda mashiinka cabbiraadda saddexda isku-dhafan (CMM) waxay si toos ah u saamaysaa isku halaynta natiijooyinka cabbirka. Xulashooyinka Granite oo leh saxnaanta 1μm, sababtoo ah sifooyinkooda jireed ee deggan iyo saxnaanta wax soo saarka oo aad u sarreysa, ayaa noqday qalab ku habboon hagaajinta mashiinnada cabbiraadda saddex isku-duwan. Kuwa soo socdaa waxay ku siin doonaan hordhac faahfaahsan oo ku saabsan tallaabooyinka gaarka ah ee lagu hagaajinayo mashiinka cabbiraadda saddex isku-duwan iyadoo la adeegsanayo xulaadda granite-ka saxda ah ee ZHHIMG® 1μm.

I. Diyaargarow ka hor inta aan la hagaajin

Hubi xaaladaha deegaanka: Hubi in heerkulka deegaanka cabbirku uu deggan yahay 20±1℃, qoyaankana la xakameeyey inta u dhaxaysa 40% iyo 60%. Isla mar ahaantaana, yaree faragelinta gariirka ee ay keento dhaqdhaqaaqa shaqaalaha iyo hawlgalka qalabka. Heerkulka joogtada ah iyo heerka qoyaanka ee aqoon-is-weydaarsiga deegaanka ee ZHHIMG® waxaa si sax ah loogu talagalay in lagu hubiyo in alaabada granite aysan saameyn ku yeelan arrimaha deegaanka inta lagu jiro habka wax soo saarka. Tani waxay sidoo kale si dadban u caddaynaysaa muhiimadda ay leedahay xaaladaha deegaanka ee cabbiraadda saxda ah.

Qalabka nadiifinta iyo qalabka: Isticmaal maro aan lahayn lakab iyo nadiifiye gaar ah si aad si taxaddar leh u tirtirto miiska shaqada, baaritaanka iyo dusha sare ee mashiinka cabbirka saddex-isku-dubaridka ah si loo hubiyo inaysan jirin boodh, wasakh saliid ama wasakh kale, si aysan u saameyn saxnaanta cabbirka.

Xaqiiji shahaadada iyo xaaladda: Xaqiiji in shahaadada cabbiraadda ee ku lifaaqan aaladda granite-ka ay ku jirto muddadii ay shaqaynaysay, oo aysan jirin xoqitaan, waxyeello ama cillado kale oo muuqda oo ku yaal dusha sare ee aaladda. Badeeco kasta oo ZHHIMG® ah waxay martaa tijaabo adag waxayna ku qalabaysan tahay shahaadooyin tijaabo oo rasmi ah si loo hubiyo in saxnaanta badeecaddu ay buuxiso heerarka.

Ii. Tallaabooyinka Hawlgalka Kala-hagaajinta

Dhig mastaradda granite-ka: Si joogto ah u dhig mastaradda granite-ka saxda ah ee 1μm miiska shaqada ee mashiinka cabbiraadda saddexda isku-dubarid, oo isku day inaad ka dhigto mid barbar socda dhidibyada isku-dubaridka ee mashiinka cabbiraadda. Isticmaal qalab gaar ah ama saldhig birlab ah si aad u hagaajiso si aad uga hortagto mastaradda inay dhaqaaqdo inta lagu jiro habka cabbiraadda.

Bilaabidda baaritaanka iyo booska: Bilow mashiinka cabbiraadda saddexda isku-dubarid ah oo samee hawlgallada bilowga ah ee baaritaanka si loo hubiyo inuu ku jiro xaalad shaqo oo caadi ah. Kadib, xakamee madaxa cabbiraadda ee mashiinka cabbiraadda si uu si tartiib tartiib ah uga gudbo barta cabbirka bilowga ee xudunta granite-ka, adigoo isu diyaarinaya cabbirka.

Qaado celceliska qiimaha cabbirka dhibcaha badan leh: Jihada dhererka ee mastaradda granite-ka, si isku mid ah u dooro ugu yaraan shan dhibcood oo cabbir ah (sida barta bilowga, 1/4 dhibcood, bartamaha, 3/4 dhibcood, iyo barta dhammaadka), xakamee baaritaanka si uu u sameeyo cabbirka xiriirka ee dhibic kasta oo cabbir ah si isku xigxig ah, oo u diiwaangeli xogta cabbirka ee dhibic kasta. Saxnaanta sare ee geesaha toosan ee granite-ka ZHHIMG® waxay hubin kartaa in xogtan cabbiraadda ay si dhab ah u muujinayso xaaladda saxnaanta mashiinka cabbiraadda.

Xisaabinta iyo habaynta khaladaadka: Isbarbardhig xogta uu duubay mashiinka cabbiraadda iyo qiimaha magacaaban ee xudunta granite si loo xisaabiyo qiimaha qaladka ee dhibic kasta oo cabbir ah. Sida waafaqsan xaaladda qaladka, nidaamka isku-dubaridka ee mashiinka cabbiraadda saddexda isku-dubaridka ah ayaa la hagaajiyaa oo si waafaqsan loo hagaajiyaa iyadoo la adeegsanayo barnaamijka cabbiraadda ee mashiinka cabbiraadda saddexda isku-dubaridka ah ilaa qaladka cabbirka lagu xakameeyo xadka la oggol yahay.

Xaqiijinta cabbirka ee soo noqnoqda: Ka dib marka la dhammaystiro cabbiraadda, mar kale ku samee cabbirro badan oo ku yaal maareeyaha granite-ka si aad u xaqiijiso saameynta cabbiraadda. Haddii qaladka u dhexeeya natiijada cabbirka iyo qiimaha magac-u-yaalka uu ku jiro ±1μm, waxay muujinaysaa in cabbiraadda ay guuleysatay. Haddii qaladku uu aad u weyn yahay, tallaabooyinka hawlgalka waa in dib loo hubiyaa. Haddii loo baahdo, la xiriir xirfadlayaasha si aad u maareyso.

Iii. Dayactirka iyo Taxaddarrada ka dib Hagaajinta

Si habboon u kaydi mastaradda: Ka dib marka shaqada cabbiraadda la dhammeeyo, ku masax mastaradda granite maro nadiif ah oo aan lahayn lakab, ku rid sanduuq baakad oo gaar ah ama kiis ilaalin ah, oo ku kaydi jawi qalalan oo heerkul joogto ah si looga hortago in mastaraddu qoyaan ama dhaawacdo.

Habaynta joogtada ah: Si loo hubiyo saxnaanta cabbirka muddada dheer ee mashiinka cabbiraadda, waxaa lagu talinayaa in lagu habeeyo mashiinka cabbiraadda saddexda-isku-dubaridka leh mastarad granite sax ah oo 1μm ah 3 ilaa 6 bilood kasta. Isla mar ahaantaana, marka mashiinka cabbiraadda uu maro gaadiid, dayactir ama isbeddello muhiim ah oo ku yimaada xaaladaha deegaanka, habaynta waa in sidoo kale lagu sameeyaa waqtigeeda.

Hawlgalka Caadiga ah: Inta lagu jiro isticmaalka maalinlaha ah, si adag u raac habraacyada hawlgalka si aad u isticmaasho mashiinka cabbiraadda saddexda isku-dubarid iyo mastaradda granite-ka si looga fogaado dhaawaca qalabka ama qalabka sababtoo ah hawlgal aan habboonayn, taas oo saameyn karta saxnaanta cabbirka.

Tallaabooyinka kor ku xusan, ZHHIMG® 1μm saxnaanta granite-ka ayaa si wax ku ool ah loogu isticmaali karaa in lagu cabbiro mashiinka cabbiraadda saddexda isku-dubbaridan, iyadoo la hubinayo saxnaanta iyo isku hallaynta natiijooyinka cabbiraadda iyo bixinta dammaanad adag oo ku saabsan shaqada cabbirka saxda ah.

Waqtiga boostada: Juun-18-2025