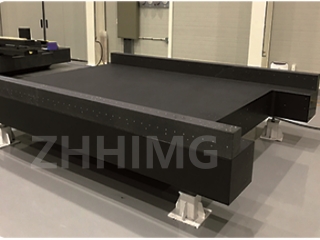

Granite sax ah ayaa si weyn loogu isticmaalaa warshado kala duwan sida injineernimada farsamada, metrology, iyo warshadaha indhaha. Maaddadani waxaa loo yaqaanaa xasilloonideeda aadka u fiican, cimri dhererkeeda, iyo saxnaanteeda. Si kastaba ha ahaatee, waqti ka dib, granite sax ah ayaa waxyeelloobi kara sababtoo ah xirashada iyo jeexitaanka, saameynta shilalka, ama soo-gaadhista heerkulka aadka u daran. Tani waxay wax u dhimi kartaa saxnaanteeda waxayna saameyn kartaa muuqaalkeeda.

Haddii aad la kulanto dhibaatadan, ha welwelin. Maqaalkan, waxaan kugu hagi doonnaa tallaabooyinka lagu hagaajinayo muuqaalka granite-ka saxda ah ee dhaawacan, iyo dib u habaynta saxnaantiisa. Waa muhiim in la ogaado in tallaabooyinkan ay u baahan yihiin in uu fuliyo xirfadle xirfad leh oo leh qalabka iyo qalabka saxda ah.

Dayactirka muuqaalka Granite-ka Sax ah ee dhaawacan:

Tallaabada 1aad: Nadiifinta Dusha Sare: Tallaabada ugu horreysa ee lagu hagaajinayo muuqaalka granite-ka saxda ah waa in la nadiifiyo dusha sare. Isticmaal maro jilicsan iyo nadiifiye aan xoqin si aad uga saarto wasakhda, boodhka, ama qashinka. Haddii dusha sare ay dufan tahay, isticmaal saliid tirtire oo biyo ku raaci.

Tallaabada 2: Baarista Dusha Sare: Baar dusha sare si aad u aqoonsato baaxadda iyo nooca burburka. Noocyada burburka qaarkood waxaa lagu hagaajin karaa nadiifin fudud, halka kuwa kalena ay u baahan yihiin farsamooyin horumarsan.

Tallaabada 3: Nadiifinta Dusha Sare: Xoqitaanno yaryar ayaa lagu sifeyn karaa iyadoo la isticmaalayo isku-darka rinjiyeynta iyo maro jilicsan. Hubi inaad isticmaasho isku-darka ku habboon dusha sare ee granite-ka saxda ah. Isku-darka rinjiyeynta waa in lagu mariyaa dhaqdhaqaaq wareeg ah oo lagu tirtiraa maro nadiif ah.

Xoqitaan qoto dheer awgeed, suufka dheemanka lagu nadiifiyo ayaa la isticmaali karaa. Suufka waa in lagu dhejiyaa nadiifiye xawaare kala duwan leh oo loo isticmaalaa xawaare gaabis ah si looga fogaado in dusha sare uu waxyeello dheeraad ah u geysto. Suufka waa in loo dhaqaajiyaa dhaqdhaqaaq wareeg ah, iyadoo la isticmaalayo biyo saliid ahaan.

Tallaabada 4: Buuxinta Dildilaaca iyo Jajabyada: Haddii ay jiraan dildilaacyo ama jajabyo dusha sare ah, waa in lagu buuxiyaa iyadoo la isticmaalayo resin epoxy ah. Resinka waa in lagu qaso sida ku cad tilmaamaha soo saaraha oo lagu mariyo meesha ay dhibaatadu saameysey. Ka dib marka resinku dego, waxaa lagu shiidayaa ilaa heerka dusha sare ee ku wareegsan.

Dib-u-hagaajinta saxnaanta Granite-ka Sax ah:

Tallaabada 1aad: Hubinta Saxnaanta: Kahor inta aan dib loo habeyn granite-ka saxda ah, waa muhiim inaad hubiso saxnaantiisa hadda jirta. Tan waxaa lagu samayn karaa iyadoo la adeegsanayo qalab sax ah sida qalabka interferometer-ka laysarka ama baloogyada cabbirka.

Tallaabada 2aad: Aqoonsiga Dhibaatada: Haddii saxnaanta la ogaado inay maqan tahay, tallaabada xigta waa in la aqoonsado dhibaatada. Tani waxay ku lug yeelan kartaa baaritaanka dusha sare si loo ogaado burburka, hubinta isku xirnaanta mashiinka, ama hubinta saxnaanta qalabka cabbiraadda.

Tallaabada 3: Hagaajinta Dusha Sare: Haddii dusha sare ee granite-ka saxda ah la ogaado inuu yahay mid aan sinnayn, waxaa lagu hagaajin karaa iyadoo la adeegsanayo hab loo yaqaan laalaab. Laalaabku wuxuu ku lug leeyahay xoqidda dusha sare ee granite-ka xoqid yar si looga saaro meelaha sare loona abuuro dusha sare oo siman.

Tallaabada 4: Hubinta Isku-xidhka: Haddii dhibaatadu la ogaado inay la xiriirto isku-xidhka mashiinka, waa in la hagaajiyaa si loo hubiyo inay la siman tahay dusha sare ee granite-ka saxda ah. Tan waxaa lagu samayn karaa iyadoo la adeegsanayo shims sax ah ama boolal hagaajin ah.

Tallaabada 5: Dib-u-habaynta Qalabka: Marka granite-ka saxda ah la hagaajiyo oo sax noqdo, waa muhiim in dib loo habeeyo qalabka cabbiraadda ee loo isticmaalay. Tani waxay ku lug yeelan kartaa hagaajinta eber-ka dhibicda, hagaajinta miisaanka, ama beddelidda qaybaha duugoobay.

Gunaanad ahaan, granite-ka saxda ah waa walax qiimo leh oo u baahan dayactir taxaddar leh si loo hubiyo saxnaantiisa iyo cimri dhererkiisa. Markaad raacdo tallaabooyinka ku xusan maqaalkan, waxaad hagaajin kartaa muuqaalka granite-ka saxda ah ee dhaawacan oo aad dib u habayn kartaa saxnaantiisa si aad u hubiso inay weli tahay qalab lagu kalsoonaan karo warshadahaaga.

Waqtiga boostada: Oktoobar-09-2023